Capabilities | Tooling

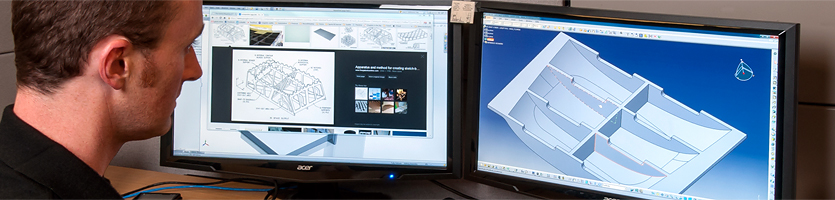

Tooling

As a one-stop source for tool design and tool procurement, LMI has strong relationships with high-quality fabrication suppliers. We work together to deliver the right tools for our customers. Our suppliers have been audited and approved by our AS9100-certified quality team and meet quality standards for delivery. As always, we strictly adhere to ITAR/EAR compliance requirements and all applicable export control regulations.

Proven Experience

For the past 30 years, we've provided tooling services to the U.S. Navy, The Boeing Company, Spirit Aerosystems (Wichita), AIT, MHI, Janicki and many others. Past projects have included everything from large wing-to-body joint assembly tooling to smaller drill jigs and other fixtures required for precision assembly of aircraft structures. Current tooling support programs include composite bond tools, assembly and installation tools, metallic structure assembly, and installation jigs.

Wide Range of Tooling Capabilities

- Assembly jigs, including fuselage, wings, control surfaces, space vehicles

- Composite lay-up mandrels

- Handling equipment and scaffolding

- Mill fixtures/CNC routing fixtures

- Ground support equipment and fixturing

- Shipping fixtures

- Aircraft modification and service life extension tooling

- Invar and aluminum tooling

- Drill jigs

- Special machinery and equipment

More Tooling-Related Services

- Manufacturing and factory/facilities planning

- CNC programming

- Tooling analysis and documentation

Facebook

Facebook Twitter

Twitter  LinkedIn

LinkedIn