Capabilities | Design Build

A Streamlined Process

Building and maintaining your own in-house staff, or contracting with numerous suppliers, is costly and time-consuming. With LMI, you have one contract for all of the services you need. This simplifies and speeds up the design-build process. Our outstanding customer service keeps you informed on the status of your project, and our highly skilled project managers make sure your project is delivered on time and on budget.

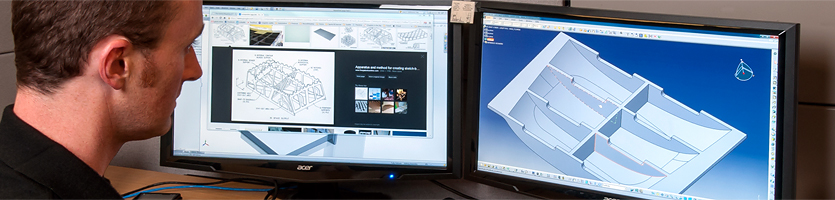

One Integrated Team

Integrating our manufacturing engineers into the design build process helps ensure that your project progresses smoothly through the design-to-production process. Supported by common software and a single network across all locations, we are able to readily share data, optimize configuration control, meet engineering and technical requirements at first-build, and provide more producible, lower cost deliverables. Shorter time to market, a higher quality product and more savings are hallmarks of our integrated approach.

Key Benefits

- Save Time & Money — Work with one integrated team, not multiple suppliers

- Increase Efficiency — Meet all requirements the first time through the manufacturing cycle

- Simplify Management — Focus on your priorities rather than on the engineering details

- Ensure Quality — Get the best product from the best people, processes and approach

- Risk Management — Spread the development risk to a qualified supplier

Proven Experience

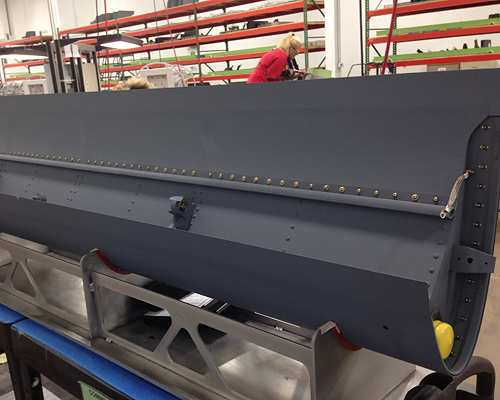

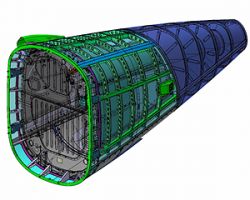

Mitsubishi Regional Jet - Tailcone Assembly

Responsible for Design/Development/Testing/Quality/Production

- Structure Design & Analysis, Thermal & Acoustic Analysis, and Systems Testing

- Inlet/Exhaust Design, Integration with Aux Power Unit (APU)

- Technical Publication Source Data, Production Tooling

- Product Lifecycle Management System implemented at LMI to support Configuration Management/Control

- 7 LMI Locations Associated with MRJ Tailcone

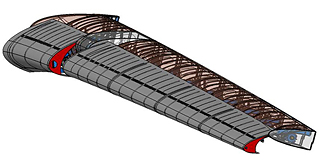

Embraer KC-390 - Slat Assemblies

Responsible for Design/Development/Testing & Quality/Production

- 5 Moving Slat Assemblies per Wing

- Structure Design, Analysis, & Structures Test Interface with Leading Edge Structure

- Technical Publication Source Data, Production Tooling

- 9 LMI Locations Associated with KC-390 Slats

Facebook

Facebook Twitter

Twitter  LinkedIn

LinkedIn